Optimizing Granulation for Tableting: A Technical Guide

Achieving precise particle sizing for Calcium Carbonate granulation is crucial for meeting the rigorous demands of tablet production. As end customers increasingly scrutinize trace metal levels and purity standards, navigating these specifications can pose challenges.

Particle Size Optimization: Granulation lines operate most efficiently within specific size ranges, tailored to meet the compaction requirements for tablet compression strength. Essential Minerals offers a comprehensive range of particle sizes, striking the perfect balance between narrow and broad distributions. Our PureCal products ensure the majority of particles align with the target median, while still providing ample variation to fill voids and enhance compaction—a win-win solution for both granulators and tablet manufacturers.

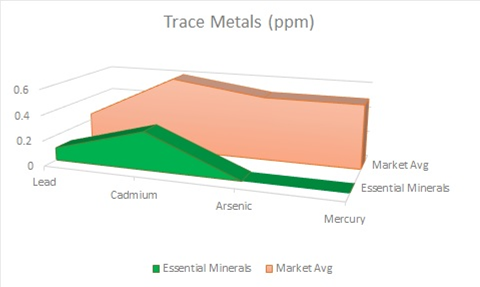

Trace Metal Compliance: With Essential Minerals' PureCal products, granulators can confidently meet stringent trace metal regulations. Our all-natural Calcium Carbonate boasts the lowest levels of Lead, Cadmium, Arsenic, Mercury, and Aluminum available in the market, aligning with regulations such as Prop 65. Additionally, our products meet the rigorous standards of Class I ICH Q3D, ensuring compliance with the most stringent industry requirements.

Technical Expertise and Support: Benefit from our extensive technical knowledge and expertise in granulation optimization. We are dedicated to demonstrating our capabilities and assisting you in achieving your production goals with confidence. For granulation solutions that exceed expectations, trust Essential Minerals.